| Bore | 3.7in |

|---|---|

| Displacement | 201in³ |

| Emissions | *The Cat C3.3B DIT engine meets EU Stage V/U.S. EPA Tier 4 Final emission standards. |

| Engine Model | Cat® C3.3B DIT* |

| Maximum Gross Power | 73.2HP |

| Maximum Gross Power - ISO 14396 | 73.2HP |

| Maximum Gross Power - ISO 14396 (metric) | 74.2HP |

| Maximum Gross Torque - ISO 14396 | 192ft·lbf |

| Maximum Net Torque - ISO 9249 | 191ft·lbf |

| Note (1) | Net power ratings are tested at the reference conditions for the specified standard. |

| Note (2) | Net power shown is the power available at the flywheel when the engine is equipped with alternator, air cleaner, diesel exhaust filter, and fan at minimum speed. |

| Note (3) | No derating required up to 3000 m (10,000 ft) altitude. Auto derate protects hydraulic and transmission systems. |

| Note (4) | Flywheel per the SAE reference conditions with the fan at maximum speed. |

| Note (5) | The Cat C3.3B DIT Tier 4 Final/Stage V uses an active regeneration system which requires no operator interaction under normal conditions. |

| Note (6) | Stage V engine available for Europe only. |

| Rated Net Power - 2,400 rpm - ISO 9249 | 72.9HP |

| Rated Net Power - 2,400 rpm - SAE J1349 | 71.9HP |

| Stroke | 4.7in |

| Note | Specifications shown are for a machine configured with general purpose buckets, bolt-on cutting edges, 75 kg (165 lb) operator, Dunlop 405/70 SPT9 tires, full fuel, comfort ROPS cab, standard flow hydraulics and skid-steer coupler. The 906M is configured |

|---|---|

| Operating Weight | 12346lb |

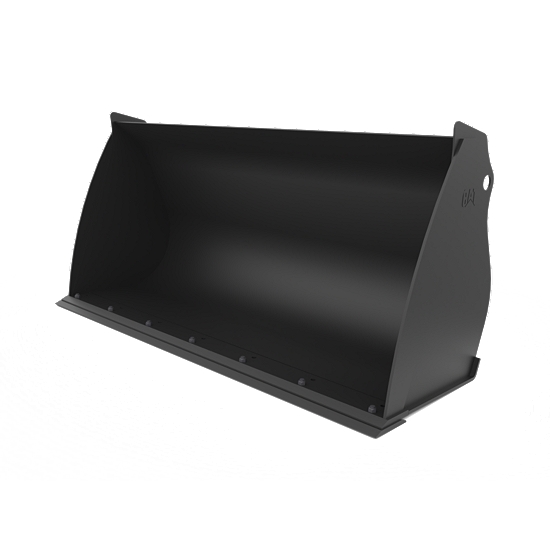

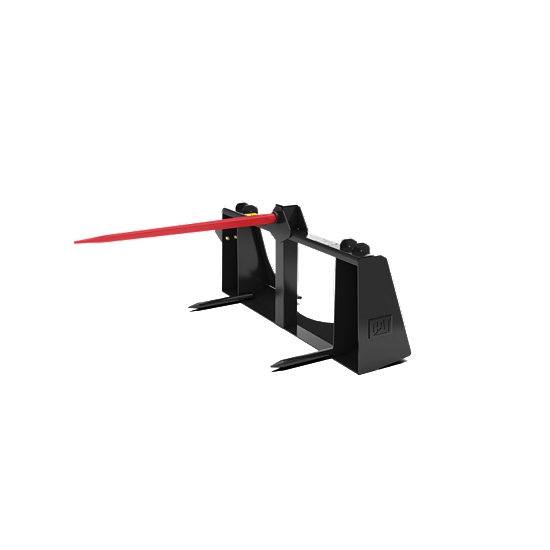

| Bucket Capacities | 0.75-1.5 m3 (1.0-2.0 yd3) |

|---|---|

| Bucket Capacities - ISO Coupler | 0.75-1.5 m3 |

| Bucket Capacities - SSL Style Coupler | 1.0-2.0 yd3 |

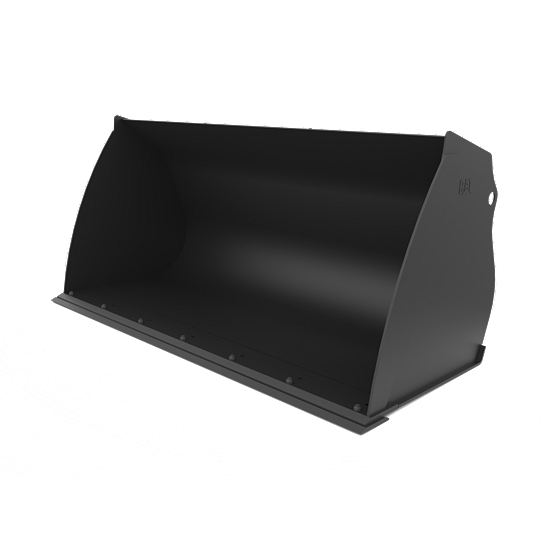

| General Purpose | 0.8 m³ (1 yd³), 0.9 m³ (1.2 yd³), 1.0 m³ (1.3 yd³), 1.1 m³ (1.4 yd³), 1.3 m³ (1.7 yd³) |

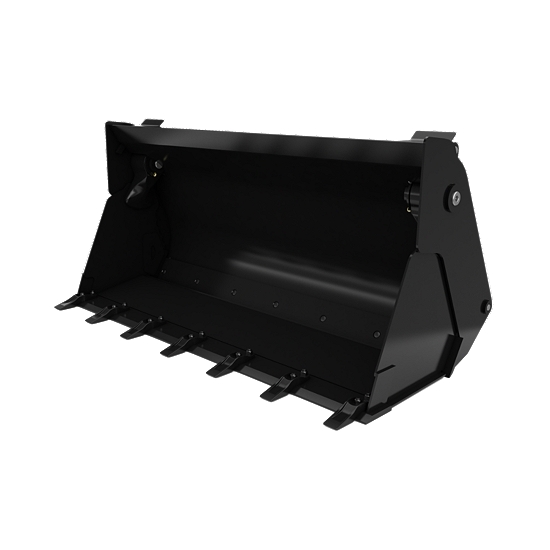

| Grapple | 0.9 m³ (1.2 yd³) heaped |

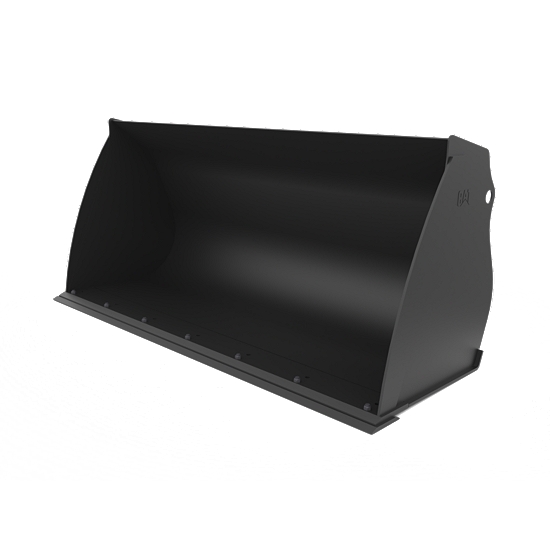

| Light Material | 1.2 m³ (1.6 yd³), 1.5 m³ (2.0 yd³) |

| Multi-Purpose | 0.75 m³ (1.0 yd³), 0.9 m³ (1.2 yd³), 1.05 m³ (1.37 yd³) |

| Note | All capacities are applicable for each model. Bucket selection must be made with an understanding of the material density and application to ensure machine stability is maintained within the tipping loads stated per model and configuration. |

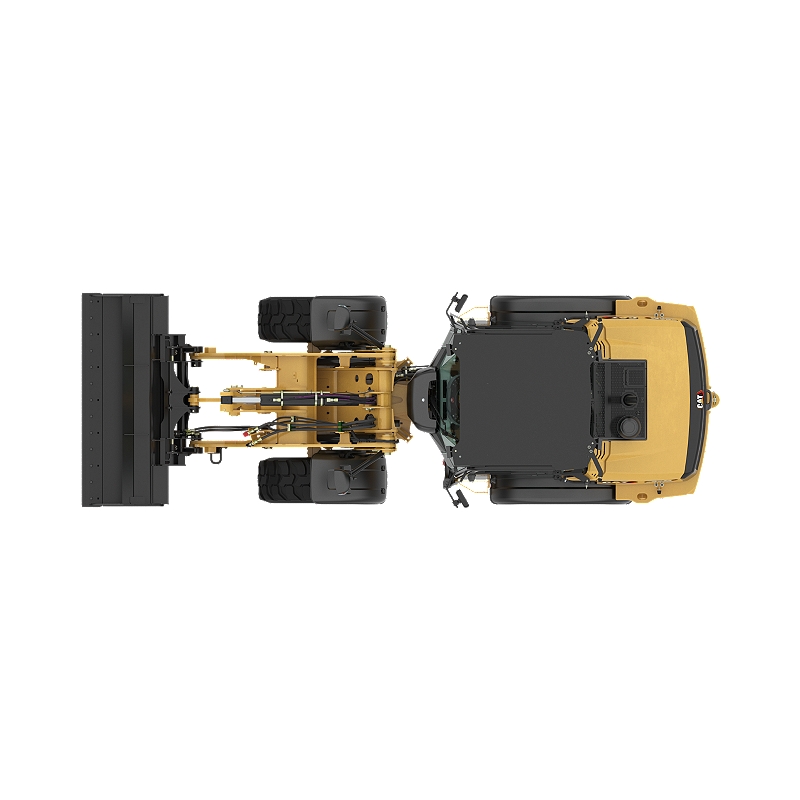

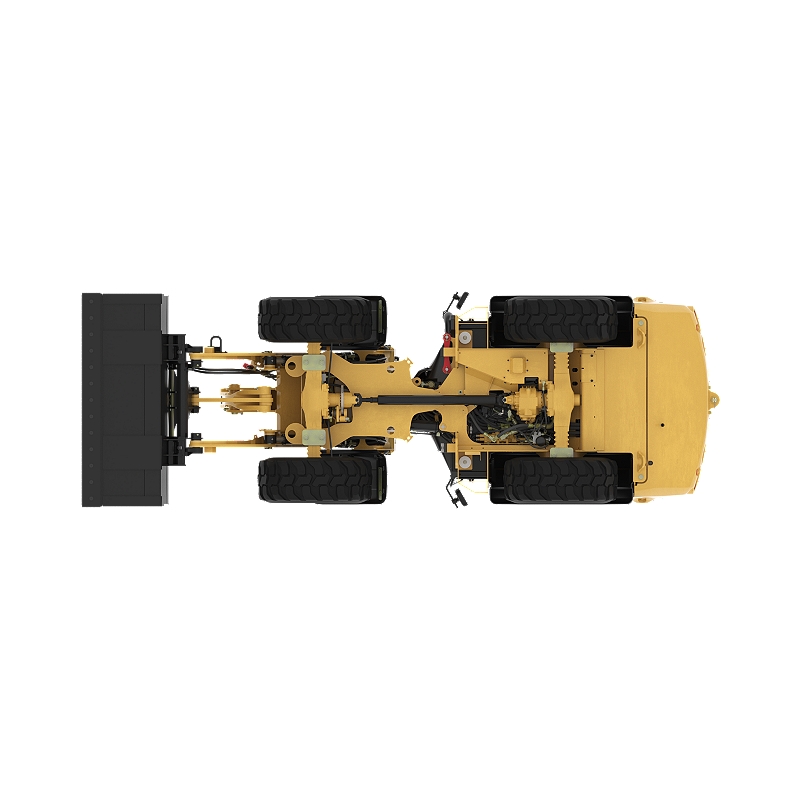

| Articulation Angle | 39° |

|---|---|

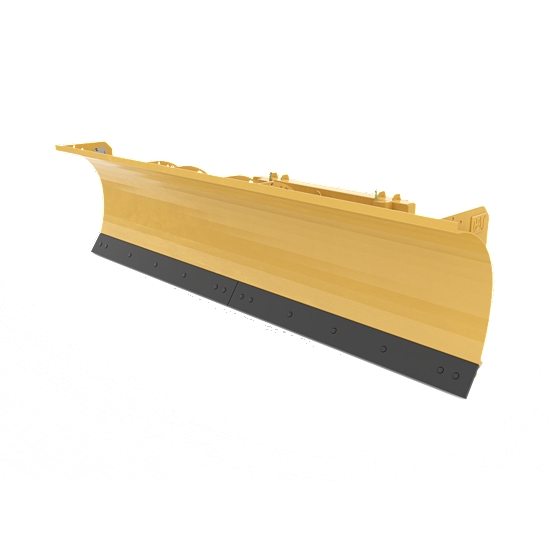

| Clearance - Bucket at 45° * | 7.67ft |

| Clearance - Level Bucket** | 9.92ft |

| Departure Angle | 33° |

| Dig Depth** | 4.2in |

| Dump Angle at Full Lift | 45° |

| Height - Bucket Pin** | 10.58ft |

| Height - Ground Clearance** | 11in |

| Height - Ground to Cab** | 8.08ft |

| Length - Overall* | 18.42ft |

| Length - Wheel Base | 7.08ft |

| Machine Width | 6ft |

| Note (1) | *Vary with bucket. |

| Note (2) | **Vary with tire. |

| Note (3) | Dimensions listed are for a machine configured with general purpose buckets, bolt-on cutting edges, 75 kg (165 lb) operator, no air conditioner and Dunlop 405/70 SPT9 tires. |

| Operating Weight | 12481lb |

| Reach - Bucket at 45°* | 2.67ft |

| Turning Radius - Inside of Tires | 7.33ft |

| Turning Radius - Over Bucket | 14.58ft |

| Width - Bucket | 6.17ft |

| Width - Tread Center | 4.58ft |

| Maximum Steering Torque - 0° (Straight Machine) | 37155ft·lbf |

|---|---|

| Maximum Steering Torque - 39° (Full Turn) | 27747ft·lbf |

| Maximum Working Pressure - Steering Pump | 3191psi |

| Nominal Flow - Steering Pump | 12gal/min |

| Number of Steering Wheel Turns - Full Left to Full Right or Full Right to Full Left | <6 turns |

| Steering AC Cycle Times - Full Left to Full Right - 2,620 rpm | 3s |

| Steering Articulation Angle - Each Direction | 39° |

| Steering Cylinder, Double Acting - Bore Diameter | 3.1in |

| Steering Cylinder, Double Acting - Rod Diameter | 1.4in |

| Steering Cylinder, Double Acting - Stroke | 11.8in |

| FOPS | FOPS: ISO 3449:2005 Level II |

|---|---|

| Note (1) | Cat cab and Rollover Protective Structures (ROPS) are standard in North America and Europe. |

| Note (2) | The declared dynamic operator Sound Pressure level per ISO 6396:2008*, when the cab is properly installed and maintained, is 75 dB(A). The labeled sound power level for the CE marked configurations when measured according to the test procedure and conditi |

| Note (3) | *The measurements were conducted with the cab doors and windows closed. |

| ROPS | ROPS: ISO 3471:2008 |

| Forward - High Range | 22mile/h |

|---|---|

| Forward - Range 1 | 6mile/h |

| Forward - Range 2 | 12mile/h |

| Reverse - High Range | 22mile/h |

| Reverse - Range 1 | 6mile/h |

| Reverse - Range 2 | 12mile/h |

| Note (1) | *Standard tire. |

|---|---|

| Note (2) | Other tire choices available, contact your Cat dealer for details. |

| Note (3) | In certain applications, the loader's productive capabilities may exceed the tires' tonnes-km/h (ton-mph) capabilities. |

| Note (4) | Caterpillar recommends that you consult a tire supplier to evaluate all conditions before selecting a tire model. |

| Option (1) | 335/80 R18 XZSL Michelin |

| Option (2) | 340/80 R18 AT-R Firestone |

| Option (3) | 340/80 R18 XMCL Michelin |

| Option (4) | 340/80 R18 TRI2 Nokian |

| Option (5) | 340/80 R18 Bibload Michelin |

| Option (6) | 405/70 R18 SPT9 Dunlop* |

| Option (7) | 12.5/80 R18 Flexport™ |

| Cooling System | 4.4gal (US) |

|---|---|

| Engine Oil | 3gal (US) |

| Fuel Tank | 13.7gal (US) |

| Hydraulic System - Including Tank | 18.5gal (US) |

| Hydraulic Tank | 12.2gal (US) |

| Transmission - Gear Box | 2.2gal (US) |

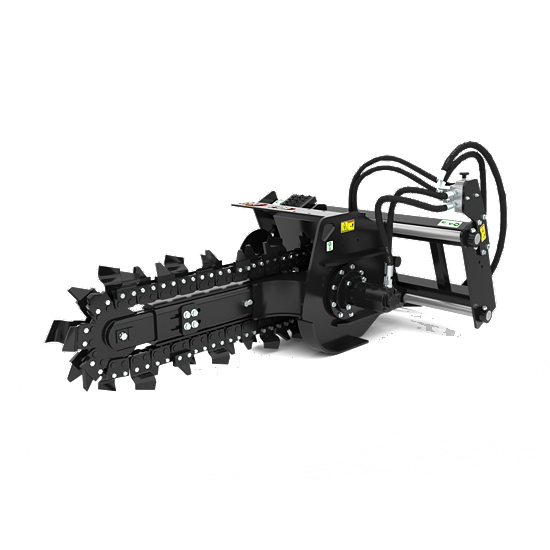

| 3rd Function Maximum Working Pressure | 3408psi |

|---|---|

| Boost Flow Maximum Pressure | 3191psi |

| Hydraulic Cycle Time - 1,000 rpm - Dump, at Maximum Lift Height | 3s |

| Hydraulic Cycle Time - 1,000 rpm - Float Down, Maximum Lift to Ground Level | 2.6s |

| Hydraulic Cycle Time - 1,000 rpm - Raise, Ground Level to Maximum Lift | 9.6s |

| Hydraulic Cycle Time - 1,800 rpm - Dump, at Maximum Lift Height | 1.5s |

| Hydraulic Cycle Time - 1,800 rpm - Float Down, Maximum Lift to Ground Level | 2.6s |

| Hydraulic Cycle Time - 1,800 rpm - Raise, Ground Level to Maximum Lift | 5.5s |

| Hydraulic Cycle Time - 1,800 rpm - Total Cycle Time | 9.6s |

| Lift Cylinder, Double Acting - Bore Diameter | 3in |

| Lift Cylinder, Double Acting - Rod Diameter | 2in |

| Lift Cylinder, Double Acting - Stroke | 27.4in |

| Maximum Flow - Implement Pump | 19gal/min |

| Maximum Flow - Implement Pump - Auxiliary Function High Flow | 31gal/min |

| Maximum Flow - Implement Pump - Auxiliary Function Standard Flow | 19gal/min |

| Maximum Working Pressure - Implement Pump | 3408psi |

| Relief Pressure - Tilt Cylinder Head | 4496psi |

| Relief Pressure - Tilt Cylinder Rod | 2756psi |

| Tilt Cylinder, Double Acting - Bore Diameter | 3.5in |

| Tilt Cylinder, Double Acting - Rod Diameter | 2.2in |

| Tilt Cylinder, Double Acting - Stroke | 16.4in |

| Clearance - Full Lift and 45° Dump | 8.24ft |

|---|---|

| Full Turn Tipping Load | 7507lb |

| Rated Bucket Capacity | 1.2yd³ |

| Reach - Full Lift and 45° Dump | 2.34ft |

| Steering Articulation Angle - Each Direction | 39° |

| Tipping Load - Full Turn - ISO 14397-1 | 7061lb |

| Tipping Load - Straight - ISO 14397-1 | 8666lb |

| Articulation Angle | 39° |

|---|---|

| Clearance - Bucket at 45° * | 8.08ft |

| Clearance - Level Bucket** | 9.92ft |

| Departure Angle | 33° |

| Dig Depth** | 3.7in |

| Dump Angle at Full Lift | 45° |

| Height - Bucket Pin** | 10.58ft |

| Height - Ground Clearance** | 11in |

| Height - Ground to Cab** | 8.08ft |

| Length - Overall* | 17.92ft |

| Length - Wheel Base | 7.08ft |

| Machine Width | 6ft |

| Note (1) | *Vary with bucket. |

| Note (2) | **Vary with tire. |

| Note (3) | Dimensions listed are for a machine configured with general purpose buckets, bolt-on cutting edges, 75 kg (165 lb) operator, no air conditioner and Dunlop 405/70 SPT9 tires. |

| Operating Weight | 12496lb |

| Reach - Bucket at 45°* | 2.33ft |

| Turning Radius - Inside of Tires | 7.33ft |

| Turning Radius - Over Bucket | 14.5ft |

| Width - Bucket | 6.17ft |

| Width - Tread Center | 4.58ft |