| Carga del cubo | 67ton (US) |

|---|---|

| Salida del motor - SAE J1995 | 3015hp |

| Nota | Specifications shown above apply to Face Shovel configuration. Backhoe and Frontless configurations are also available. |

| Peso operativo | 660ton (US) |

| Modelo de motor | 2 x Cat 3512E |

|---|

| Aspiración | Turbocharged and charge air-cooled |

|---|---|

| Bore | 6.69in |

| Componentes (1) | Non-DEF Aftertreatment system with Diesel Oxidation Catalysts (DOCs) |

| Componentes (2) | High-capacity water separator |

| Componentes (3) | Two-stage fuel filter with series filtration |

| Componentes (4) | Filtros de aire resistentes |

| Componentes (5) | Microprocessed engine management |

| Componentes (6) | Ventilador de radiador de accionamiento hidráulico con velocidad de ventilador controlada electrónicamente |

| Componentes (7) | Exhaust manifold and turbo heat shields |

| Desplazamiento | 3574in³ |

| Número de cilindros - cada motor | 12 |

| Velocidad nominal | 1.800 min-1 (1.800 rpm) |

| Golpe | 8.46in |

| Emisiones | Optimized for fuel consumption. |

|---|---|

| Potencia bruta - SAE J1995 | 3025hp |

| Net Power - ISO 9249 | 2990hp |

| Net Power - SAE J1349 | 2821hp |

| Emisiones | Meets U.S. EPA Tier 4 Final emission requirements. These engines participate in the U.S. EPA averaging, banking, and trading provisions. |

|---|---|

| Potencia bruta - SAE J1995 | 3015hp |

| Net Power - ISO 9249 | 2979hp |

| Net Power - SAE J1349 | 2810hp |

| Baterías en serie/ instalación en paralelo | 6 x 210 Ah; 12 V each; 630 Ah 24 V in total |

|---|---|

| Componentes (1) | 6 maintenance-free batteries |

| Componentes (2) | Lockable battery isolator switch |

| Componentes (3) | Lockable starter isolator switch |

| Componentes (4) | 13 LED high-brightness working flood lights |

| Componentes (5) | 17 LED service lights |

| Componentes (6) | 2 electric horns (1 cab module; 1 oil cooler module) |

| Voltaje del sistema | 24 V |

| 6060 FS - Ground Pressure | 26.6 N/cm2 (38.5 psi) |

|---|---|

| 6060 FS - Operating Weight | 1320110lb |

| 6060 FS - Standard Track Pads | 4,58 pies |

| Backhoe - Ground Pressure | 26.7 N/cm2 (38.7 psi) |

| Backhoe - Operating Weight | 1323860lb |

| Backhoe - Standard Track Pads | 4,58 pies |

| Nota | Operating weights include: base machine, front attachment, standard track pads, standard rock bucket, 100% fuel and lubricants. |

| Sistema de refrigeración | 211.4gal (US) |

|---|---|

| Aceite de motor | 86,6gal (US) |

| Tanque de combustible | 3136gal (US) |

| Grease Tank | 188gal (US) |

| Sistema hidráulico - incluyendo el tanque | 2483gal (US) |

| Tanque hidráulico | 1876gal (US) |

| Swing Drive | 42.4gal (US) |

| Main Pumps - Diesel Version | 8 variable swash plate pumps |

|---|---|

| Bombas principales - Flujo máximo de aceite - Versión diesel | 8 x 650 L/min (8 x 172 gal/min) |

| Máxima presión - Accesorio | 4640psi |

| Máxima presión - Bombas de oscilación | 5075psi |

| Presión máxima - Viaje | 5220psi |

| Bombas de columpio - Versión Diesel | 4 reversible swash plate pumps |

| Bombas oscilantes - Flujo máximo de aceite - Versión diesel | 4 x 352 L/min (4 x 93 gal/min) |

| Componentes | 4 cooling fans |

|---|---|

| Diámetro - Ventilador | 46 en |

| Características (1) | El sistema de refrigeración es totalmente independiente de todos los circuitos principales, es decir, la capacidad de refrigeración controlada está disponible siempre que el motor está en funcionamiento |

| Características (2) | La velocidad del ventilador y el flujo de aceite a los refrigeradores se controlan termostáticamente |

| Características (3) | Eficiencia de refrigeración extremadamente alta para asegurar una temperatura óptima del aceite |

| Características (4) | Bombas de refrigeración de engranajes que suministran aceite de alto volumen y baja presión a los ventiladores y enfriadores de aluminio. |

| Flujo de aceite de las bombas de refrigeración | 4 x 488 L/min (4 x 129 gal/min) |

| Características (1) | Limpiadores de suciedad en el anillo de balanceo para prevenir la acumulación de escombros entre el anillo de balanceo y la carrocería. |

|---|---|

| Características (2) | Circuito de giro cerrado con control de torque |

| Características (3) | Frenado hidráulico del movimiento de giro contrarrestando el control |

| Características (4) | All raceways and the internal gearing of swing ring, supplied by automatic central lubrication system |

| Máxima velocidad de giro | 3.8r/min |

| Frenos de estacionamiento | Freno de disco múltiple húmedo, accionado por muelle/desbloqueado hidráulicamente |

| Swing Drive | 4 transmisiones planetarias compactas con motores de pistones axiales |

| Anillo columpio | Rodamiento de rodillos de triple carrera con engranaje interno sellado |

| Rodillos inferiores - cada lado | 7 |

|---|---|

| Componentes (1) | HD tracks with cast double-grouser track pad |

| Componentes (2) | HD fixed axle rollers and idlers |

| Componentes (3) | Hardened running surfaces of sprockets, idlers, rollers, pad links, and teeth contact areas |

| Componentes (4) | Acoustic travel alarm (forward and reverse) |

| Componentes (5) | Sistema de tensión de vía totalmente hidráulico y autoajustable con acumulador de pistón |

| Componentes (6) | Válvula de ralentización hidráulica automática para evitar el exceso de velocidad en los viajes de descenso |

| Gradeabilidad - Unidades de viaje - Máximo | 39% |

| Máxima fuerza de tracción | 661160lb |

| Rodillos de apoyo - Cada lado | 2 más una placa de deslizamiento en el medio |

| Almohadillas de pista - Cada lado | 42 |

| Los motores de viaje - cada lado | 1 transmisión planetaria con 2 motores de pistón axial de dos etapas |

| Velocidad de viaje - 1ª Etapa - Máxima | 0,68 millas/h |

| Velocidad de viaje - 2ª Etapa - Máxima | 0.99 millas/h |

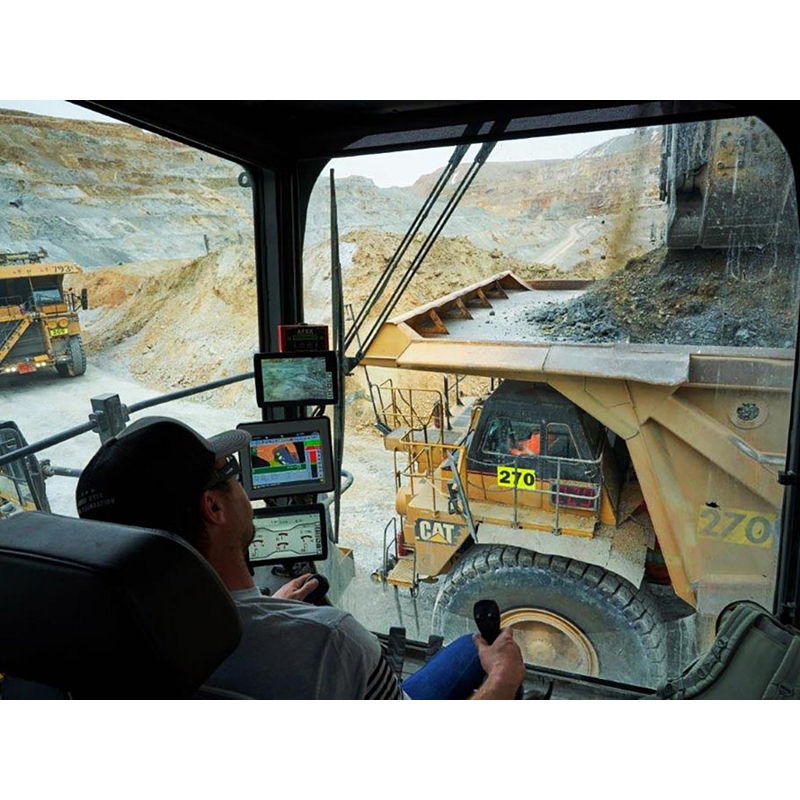

| Componentes (1) | Single hydraulically driven HVAC System, with dual system option |

|---|---|

| Componentes (10) | Powered 45 degree access stairway |

| Componentes (11) | Emergency egress ladder |

| Componentes (12) | FM/AM radio with USB and AUX input |

| Componentes (13) | Roller blinds on 3 front windows |

| Componentes (14) | 3 cup holders |

| Components (15) | Cat Electronic Technician service port |

| Componentes (2) | In-floor window with removable grate |

| Componentes (3) | Pneumatically cushioned and multi-adjustable comfort seat with heating, cooling, and lumbar support |

| Componentes (4) | Independently adjustable seat consoles with integrated joysticks |

| Componentes (5) | Operator Protective Guard (Top Guard) (ISO 10262:1998) |

| Componentes (6) | Elevated full-size trainer seat with safety belt and laptop desk |

| Componentes (7) | Additional fold-away auxiliary seat with safety belt |

| Componentes (8) | Operator Presence switch |

| Componentes (9) | Monitoring system with 254 mm (10 in) touch screen |

| Dimensiones internas de la cabina - Altura | 6,75 pies |

| Dimensiones internas de la cabina - Longitud | 7,33 pies |

| Dimensiones internas de la cabina - Anchura | 5,33 pies |

| Nivel de los ojos del operador - Aproximadamente | 24.91ft |

| Capacidad - Contenedor de grasa | 188gal (US) |

|---|---|

| Tipo (1) | Sistema de doble circuito con bombas hidráulicas de gran potencia y control electrónico de relé de tiempo para ajustar los tiempos de pausa/lubricación. |

| Tipo (2) | System failures displayed by monitoring system |

| Tipo (3) | Grease filters (200 µm) between service station and container as well as directly behind grease pump |

| Tipo (4) | Main lube system connections include: pivot points of attachment, bucket and cylinders, raceways of swing roller bearing, and 2 greasing pinions for the internal gearing of swing ring |

| Todos los cubos (FS y BH) están equipados con un paquete de desgaste que consiste en: (1) | Special liner material covering main wear areas inside and outside of bucket and lip shrouds between teeth |

|---|---|

| Todos los cubos (FS y BH) están equipados con un paquete de desgaste que consiste en: (2) | Wing shrouds on side walls and heel shrouds at bottom edges |

| El accesorio de la pala con la cinemática única TriPower asegura las siguientes características principales: (1) | Automatic roll-back limiter to prevent material spillage; Kinematic assistance to hydraulic forces |

| El accesorio de la pala con la cinemática única TriPower asegura las siguientes características principales: (2) | Horizontal Automatic constant-angle bucket guidance; Vertical Automatic constant-angle bucket guidance |

| El accesorio de la pala con la cinemática única TriPower asegura las siguientes características principales: (3) | Constant boom momentum throughout the entire lift arc; Crowd force assistance |

| Tipo (1) | Catwalks with rails at booms (FS and BH) |

| Tipo (2) | Guardias para cilindros de pala (FS) |

| Tipo (3) | Bajada sin presión de la pluma (FS y BH) y del palo (FS) mediante una válvula de flotador |

| Tipo (4) | Service access holes from both sides of boom (FS and BH) and stick (FS) |

| Tipo (5) | Los procedimientos de soldadura permiten la contra- soldadura interna (doble soldadura de preparación) siempre que sea posible |

| Tipo (6) | Las barreras y los palos se liberan de la tensión después de la soldadura. |

| Tipo (7) | Booms and sticks are torsion-resistant, welded box design of high-tensile steel with massive steel castings at pivot areas |

| Tipo (8) | Special wear packages for highly abrasive materials available upon request |

| Fuerza máxima de arranque | 388780lb |

|---|---|

| Maximum Crowd Force | 494410lb |

| Profundidad máxima de excavación | 9,17 pies |

|---|---|

| Altura máxima de excavación | 51.17ft |

| Alcance máximo de excavación | 54.17ft |

| Backhoe (heaped 1:1) | 44.5yd³ |

|---|---|

| Face Shovel (heaped 2:1) | 44.5yd³ |

| Fuerza de excavación de cubos - ISO | 274840lb |

|---|---|

| Fuerza de excavación de palos - ISO | 295740lb |

| Profundidad máxima de excavación | 29,17 pies |

|---|---|

| Altura máxima de excavación | 52.83ft |

| Alcance máximo de excavación | 62.33ft |

| Equipado con (1) | Quick couplings for: Diesel fuel, Engine coolant - left/right engine, Pump transmission gear oil - left/right engine, Engine oil - left/right engine, Hydraulic oil tank, and grease container |

|---|---|

| Equipado con (2) | El enchufe de arranque del gato |

| Equipado con (3) | Indicator lights |

| Instalación | Estación de servicio retráctil instalada debajo del módulo del motor y fácilmente accesible desde el suelo. |